In buildings where openness, brightness, and outward views are highly valued by the users of our projects, glass predominates as an exterior cladding in cities all around the world. This forces us to look for options that can manage the excess of solar radiation and maintain thermal comfort in all seasons, without obstructing the views or darkening the interior spaces.

Prefabricated metal meshes provide certain qualities and flexibility that can work well in conjunction with glass; here we present 8 tips to work with this material and take advantage of its potential.

.jpg?1520967754)

1. Avoid viewing the mesh as simply an addition to an already-defined façade

To work properly, the metal mesh must be designed in conjunction with the rest of the building, responding to its different levels, orientations, interior functions, and other specificities. Used in this way, the flexibility of the material will offer you the greatest possible advantage. However, metal mesh also enables designers to easily renovate, upgrade, or modernize existing buildings; in these cases, considering pre-existing conditions is essential for effective application.

.jpg?1520967764)

2. Consider how the mesh can deliver thermal comfort in both summer and winter

Metal meshes filter solar rays during the summer, generating shade and reducing the temperature of interiors. At the same time, in winter, their permeability allows the passage of the sun, lowering costs for heating. This forces us to think about the variable conditions of the different months of the year when designing and choosing the opening and texture of the mesh.

The interaction of the entire façade system needs to be borne in mind when using wire mesh as sun protection in combination with a glass façade. This includes the type of glazing, the incidence angle of sunlight, the distance of the wire mesh to the glass façade (ventilation), and the gloss level of the wire mesh.

3. Take advantage of air movement and mounting options to create efficient ventilated facades

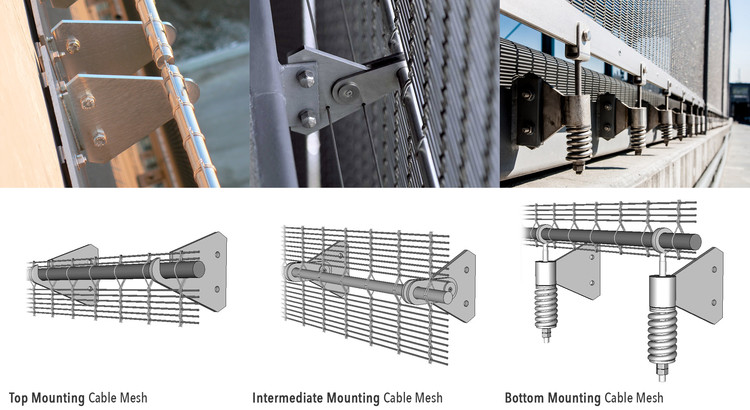

The mounting solution used for the metal mesh allows the designer to select the separation between the mesh and the glass. In this way, they can determine the right distance to generate a ventilation effect that prevents the accumulation of hot air in the extension of the façade.

.jpg?1520966252)

4. Reduce costs using minimum support points

For the installation of meshes on the entire facade, only a substructure with upper and lower joining points is required. Depending on the size of the individual elements that compose it, fixed intermediate supports must be added at each level of the building, reducing the maximum loads that act on the substructure, and the possible deflection of the mesh.

While the maximum width of the wire mesh elements is limited by production methods, the length is restricted by handling and technical considerations. In most cases, it is possible to clad façades of heights of 20 to 25 meters in single length elements. Subject to a detailed technical inspection, even longer elements can be manufactured.

.jpg?1520966564)

5. Carefully consider the user's perspective, from the inside

Although the façade can function as a thermal, shading and privacy device, with a visual impact on an urban scale, we must always consider what users will observe and feel from the interior spaces. The different patterns and levels of opening of the meshes can dramatically affect the quality of the views and the light of the living spaces.

6. Experiment with the material's flexibility of use: meshes should not always be fixed

The different installation options for metal meshes—fixed, sliding, or removable—allow a better adaptation to climatic variations, providing the option to both formally and functionally vary the façade.

7. Experiment with the forms: meshes can generate 3D effects on the facade

Cubic, cylindrical, orthogonal and freely designed forms—through prefabricated elements, dynamic 3D geometries can be generated to enhance the thermal and light comfort of the interiors. Beyond the formal variations, the mesh, which is normally used with a stainless steel look, can also be finished with different colors, digital printing, coated wires, or the wire mesh can be made of non-ferrous metal (copper, tin bronze, brass).

The interaction between artificial light and natural daylight, transparency, luminance and colour allows the façade to constantly show itself in new, stylish colors.

8. Consider incorporating light animations and large-scale video content on your facade

Metal meshes generate extensive surfaces that transform buildings into platforms for media communication. Using LED technologies, the facade can fulfill a second function at night.